Custom Parts On-Demand Manufacturing

Precision CNC Machining Solutions for Metal & Plastic Components

Get Custom QuoteOur Manufacturing Services

Comprehensive manufacturing solutions from design to finish

CNC Machining

Precision CNC milling and turning services with 3, 4, and 5-axis capabilities for complex parts and tight tolerances.

- Multi-axis machining

- ±0.005mm tolerance

- Complex geometries

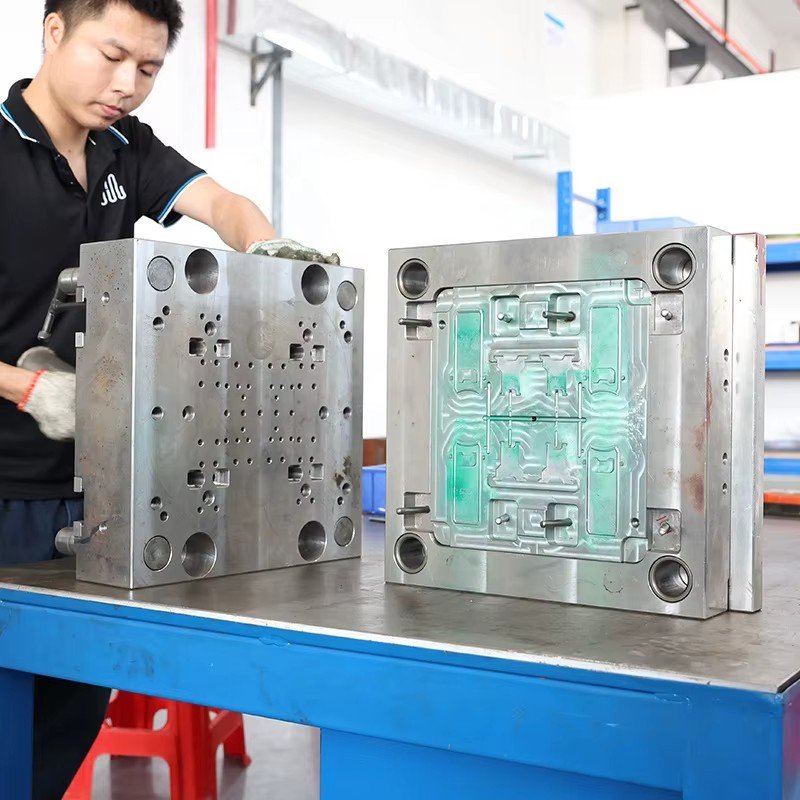

Mold Design and Manufacturing

Custom mold design and manufacturing for injection molding with precision tooling and advanced CAD/CAM capabilities.

- Custom mold design

- Precision tooling

- CAD/CAM services

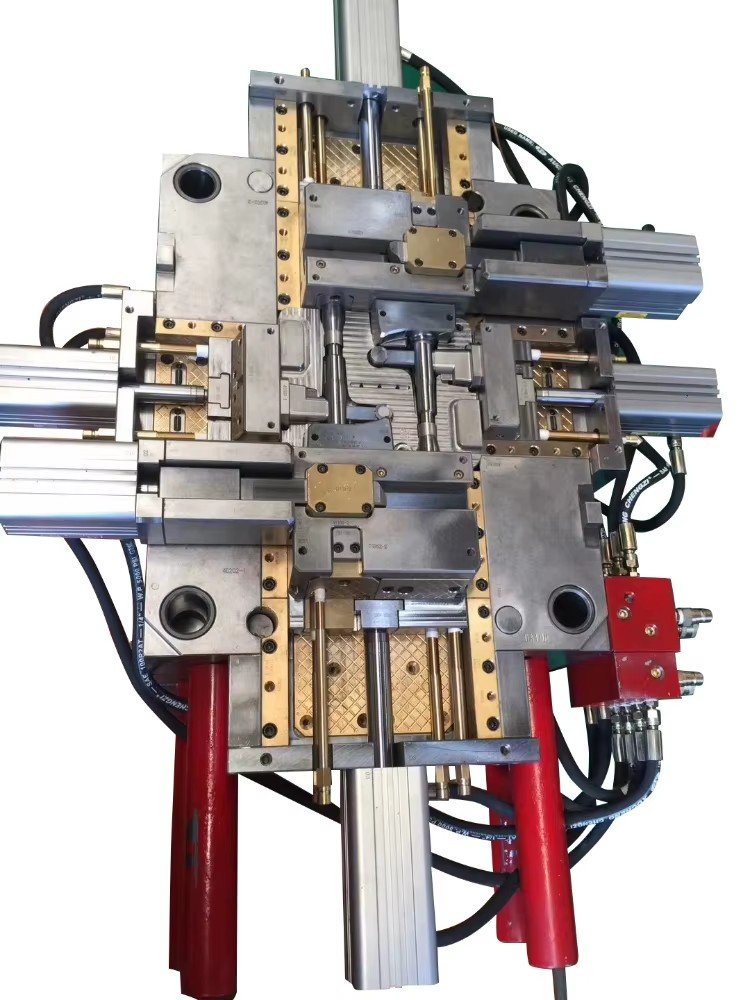

Fixture Design and Manufacturing

Specialized fixture design and manufacturing for assembly, testing, and quality control applications across industries.

- Assembly fixtures

- Testing fixtures

- Quality control tools

Sheet Metal Fabrication

Professional sheet metal fabrication services including cutting, bending, welding, and stamping for various applications.

- Laser cutting

- Precision bending

- Welding services

Metal Injection Molding

Advanced metal injection molding (MIM) technology for complex metal parts with excellent surface finish and precision.

- Complex metal parts

- High precision

- Excellent surface finish

Surface Finishing

Comprehensive surface finishing services including anodizing, powder coating, plating, and specialized treatments.

- Anodizing services

- Powder coating

- Plating & polishing

Advanced Manufacturing Technologies

State-of-the-art equipment and proven processes

5-Axis Machining

Advanced 5-axis CNC centers for complex part geometries and superior surface finishes

Automated Systems

CNC machining with robotic automation for consistent quality and improved efficiency

Quality Control

ISO 9001:2015 certified quality management with advanced inspection equipment

Comprehensive Machining Operations

- Threading (Internal/External)

- Precision Drilling

- Boring & Reaming

- Tapping & Thread Milling

- Profiling & Pocketing

- Countersinking

- Knurling & Parting

- Form Turning

Manufacturing Process

Streamlined workflow from concept to delivery

Design Review

Our engineering team analyzes your specifications and provides DFM recommendations to optimize manufacturability and cost-effectiveness.

CAM Programming

Advanced CAM programming services create optimized toolpaths for efficient machining while maintaining precision requirements.

Production

State-of-the-art CNC equipment with automated systems ensures consistent quality across medium to high volume production runs.

Quality Assurance

Comprehensive inspection and testing protocols ensure all parts meet specified tolerances and quality standards before shipment.

Material Expertise

Wide range of materials for diverse applications

Aluminum Alloys

6061, 7075, and specialty grades

Stainless Steel

304, 316, 17-4PH, and more

Tool Steels

A2, D2, O1, and specialty grades

Exotic Alloys

Titanium, Inconel, Hastelloy

Brass & Bronze

C360, C260, and bronze alloys

Engineering Plastics

PEEK, PEI, Nylon, and more

Carbon Steel

1018, 1045, and alloy steels

Cast Iron

Gray and ductile iron grades

Manufacturing Excellence

Proven track record in precision manufacturing

Years Experience

Proven expertise in custom manufacturing

Precision Tolerance

Micro-precision machining capabilities

Quality Certified

International quality management standards

Production Capacity

Continuous manufacturing operations

Frequently Asked Questions

Common questions about our custom parts manufacturing

What types of custom parts can you manufacture?

What materials do you work with?

What tolerances can you achieve?

Do you provide finishing services?

What volume production do you handle?

Are you ISO certified?

Get Your Custom Quote

Contact our team for your custom parts manufacturing needs

Contact Information

Location

Dalang Quanyongyuan Industrial Park

Longhua District, Shenzhen

Experience

11+ Years in Precision Manufacturing

Certifications

ISO 9001:2015, RoHS Compliant